Open-source and fully customizable, this robot aims to democratize lab automation, making advanced research tools accessible to scientists worldwide.

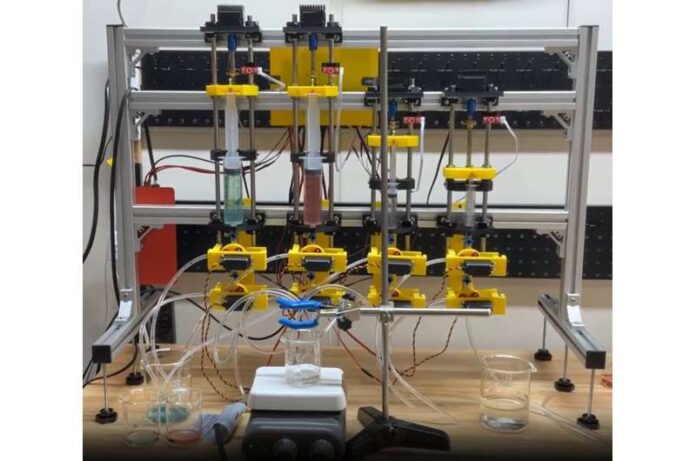

A team of scientists from Hokkaido University, led by Professor Keisuke Takahashi, has developed FLUID (Flowing Liquid Utilizing Interactive Device), a groundbreaking open-source robotic system designed for automating chemical experiments. Built using a 3D printer and affordable off-the-shelf electronic components, FLUID aims to make laboratory automation more accessible and customizable.

The team demonstrated it’s capabilities by automating the co-precipitation of cobalt and nickel—an important process in materials science—executed with remarkable precision and efficiency. “By using open-source tools, 3D printing, and widely available electronics, we created a cost-effective and adaptable robotic system tailored for specific lab needs,” said Mikael Kuwahara, the study’s lead author.

It features a modular design comprising four independent units. Each module includes a syringe, two valves, a stepper motor for accurate plunger control, and a servo motor for valve operation. End-stop sensors detect fill limits, while microcontroller boards manage the system via USB commands from a central computer.

The accompanying software provides users with real-time control over valve movements and syringe actions, along with sensor data for live status updates. Researchers can easily customize or replicate the robot thanks to the openly shared design files.

By offering a low-cost, customizable alternative to expensive commercial lab robots, FLUID opens doors for researchers worldwide—especially those in resource-limited environments or niche scientific fields where standard equipment may be unaffordable or unavailable.

Looking ahead, the team plans to enhance FLUID with additional sensors to monitor variables such as pH and temperature, enabling it to handle more complex tasks like organic synthesis and polymer mixing. The software will also receive upgrades, including macro recording for repetitive processes and improved data logging for better reproducibility. With its open-source ethos and flexible design, it stands to revolutionize how laboratories approach chemical automation.

“This approach democratizes automation in materials research,” Professor Takahashi noted. “It’s a practical, scalable solution for accelerating scientific discovery.”