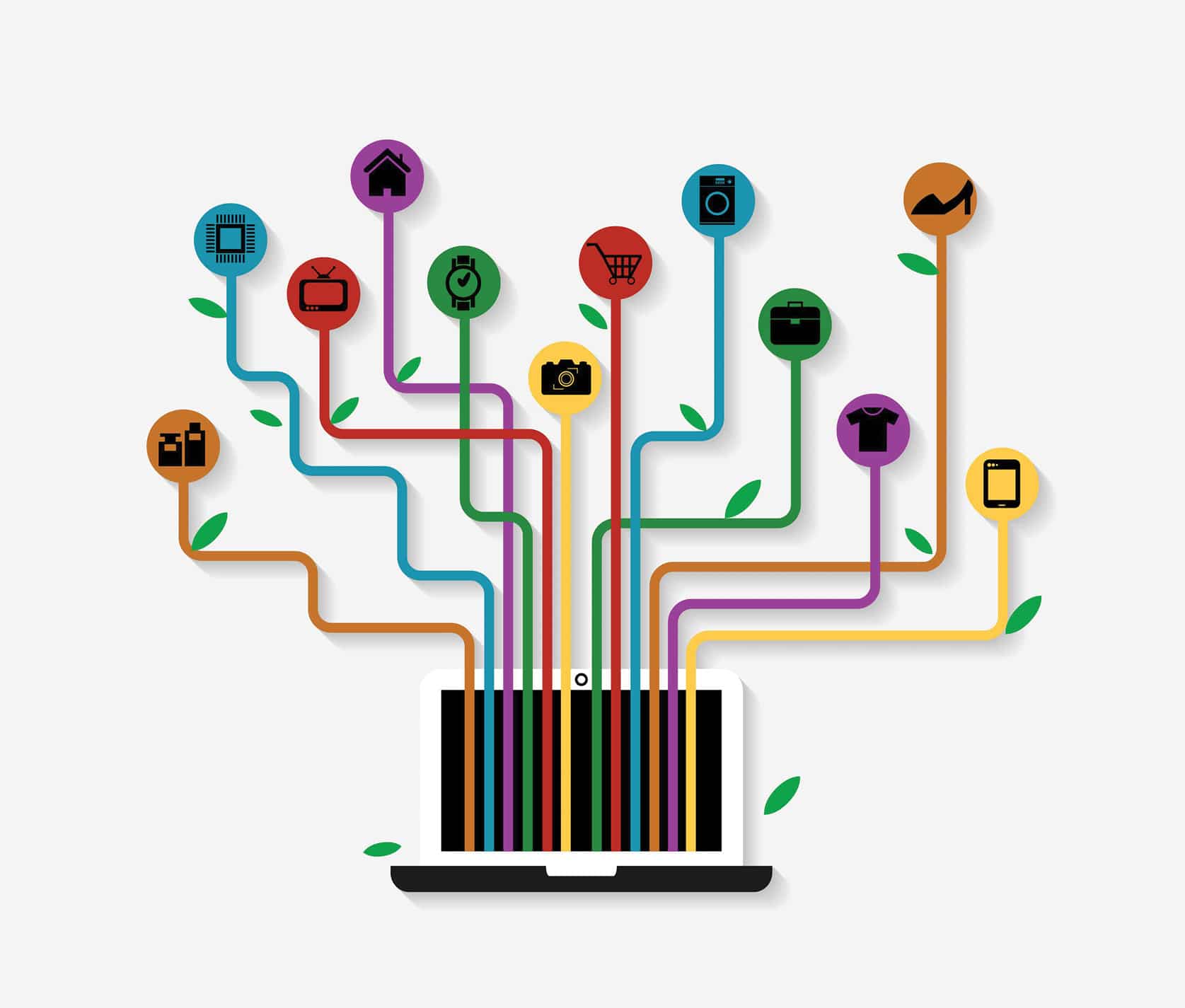

The objective is to install OPC UA FX (Field eXchange) compliant industrial field devices across the manufacturing sector and to streamline and speed their development.

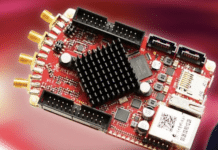

The organisations will collaborate on the creation of open source software components, the provision of reference designs and how-to manuals for sensor-to-cloud IIoT applications on various silicon platforms.

Only CPU-based controllers, such as PLCs, industrial PCs, HMIs, and Scada systems, have up to now been able to implement OPC UA. Based on low-level data for machine representation and sensor/actuator information, these controllers can offer high-level services. However, because it is aggregated, omitted, or only alerts are maintained, they often only provide a small portion of the raw data accessible from the sensors and actuators.

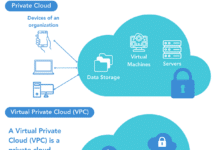

With the new endeavour, OPC UA and Ethernet TSN will be able to operate on hardware with limited processing power and memory, like microcontrollers and low-power FPGA-based SoC (system-on-chip) devices.

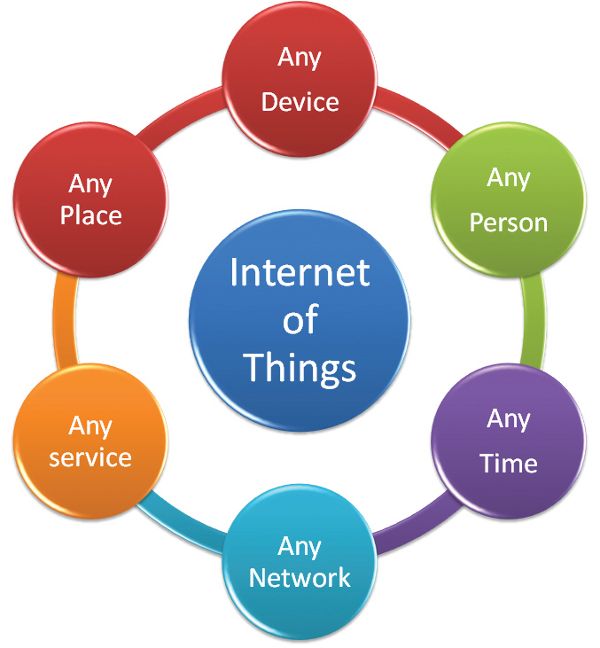

The quality of the underlying raw data determines the quality of higher-level IIoT (Industrial Internet of Things) services like predictive maintenance, cloud-based analytics, and digital twins. Unadulterated raw data must be retrieved directly from the source in order for smart manufacturing, process optimization, and adaptive systems to live up to their promises.

The consortium contends that activating OPC UA and TSN at the sensor and actuator level will provide continuous insights and data flows while still upholding zero-trust security principles. This won’t interfere with machine operations, they claim. This will result in a fieldbus system that can support the Internet of Things when combined with TSN’s real-time capabilities.