Many companies investing in open source development around IoT do not leverage open source communities. This article will help such companies understand the importance of communities and how they can help in a smart factory ecosystem.

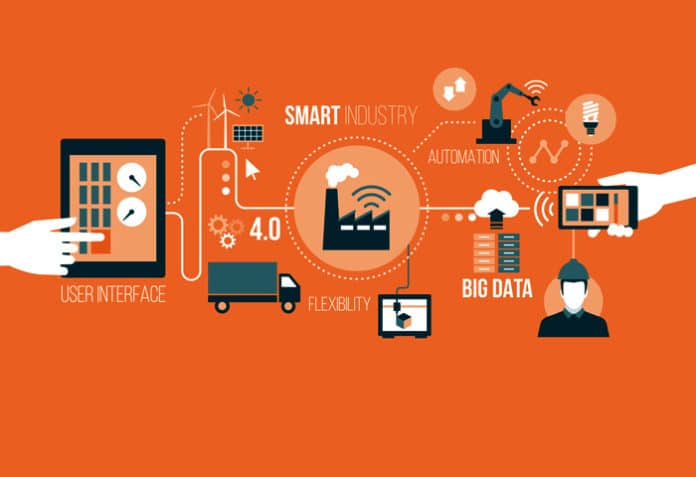

A smart factory can self-optimise performance across a broad network, self-adapt and learn from new conditions in real or near-real-time, and autonomously run entire production processes. This indicates the quantum and complexity of software required to enable, and then better a smart factory. The best technology to make these software interfaces available can be none other than open source.

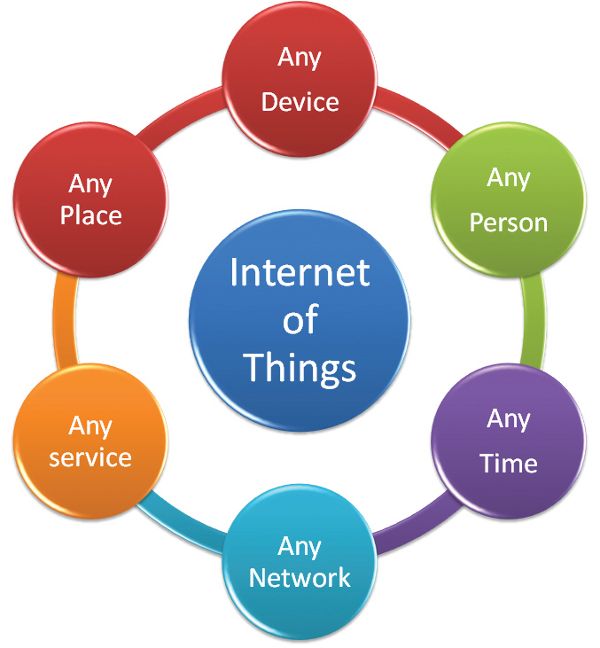

The term Internet of Things (IoT) encompasses a lot of verticals, including connected vehicles, smart transport, smart energy and resources, smart cities, digital government, digital health, and many more. Digital factories, however, are the biggest revenue generating vertical among these. This vertical accounted for more than 12,000 million Euros worth of opportunity across the globe in 2020, which is forecast to grow to more than 28,000 million Euros by 2024.

A product manufactured in a smart or a conventional factory goes through various stages. These include planning, sourcing, development, production, order processing, customer service and relationship management. Each stage has a separate goal, which aligns with the goals of other stages to generate revenue for an organisation.

IoT weds open source

Each module of product development is connected to the others, and data generated in all the stages is vital for creating and improving products. The need to create a smart factory community is strongest in the production use case.

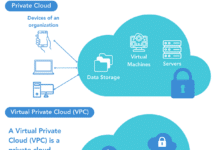

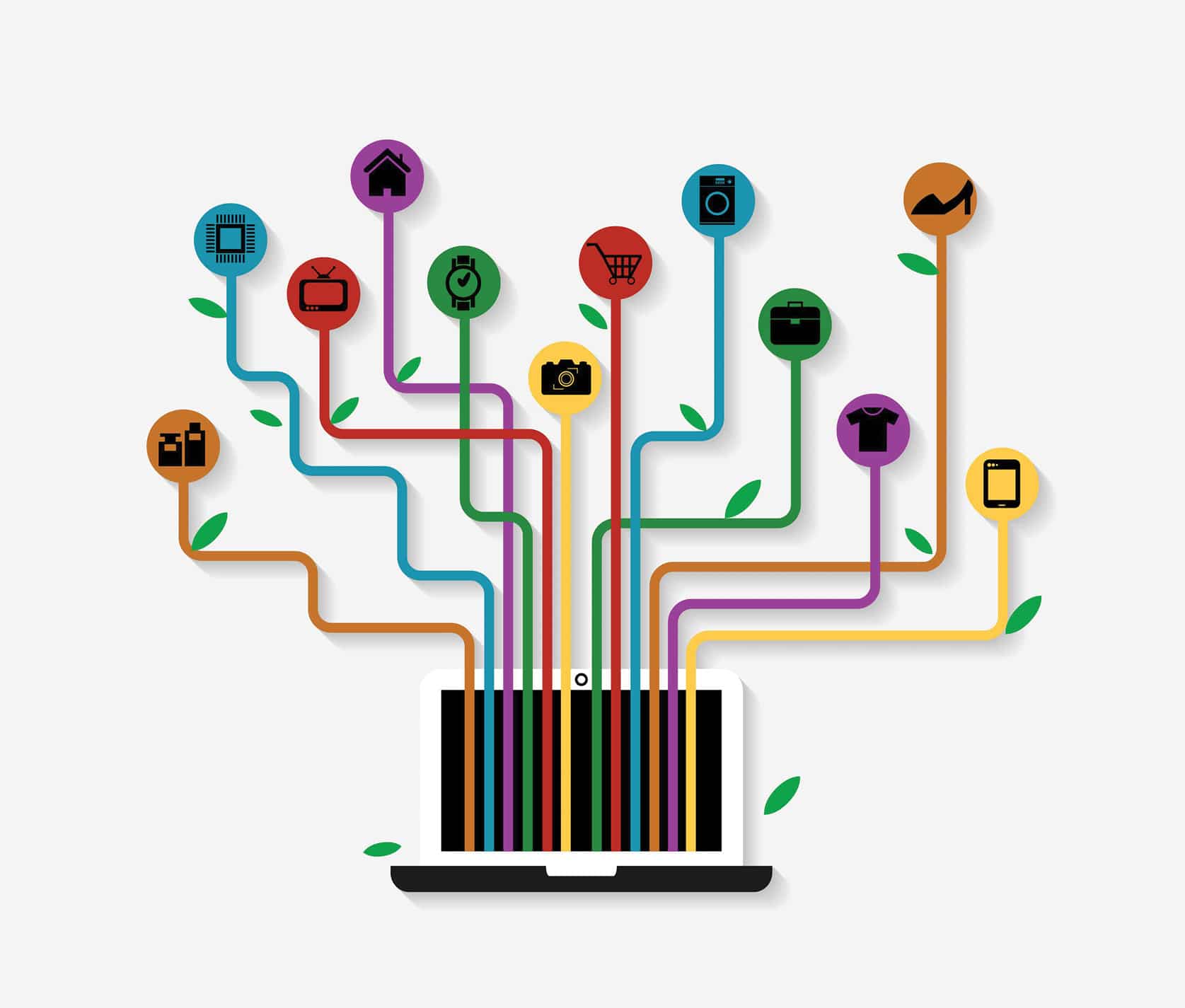

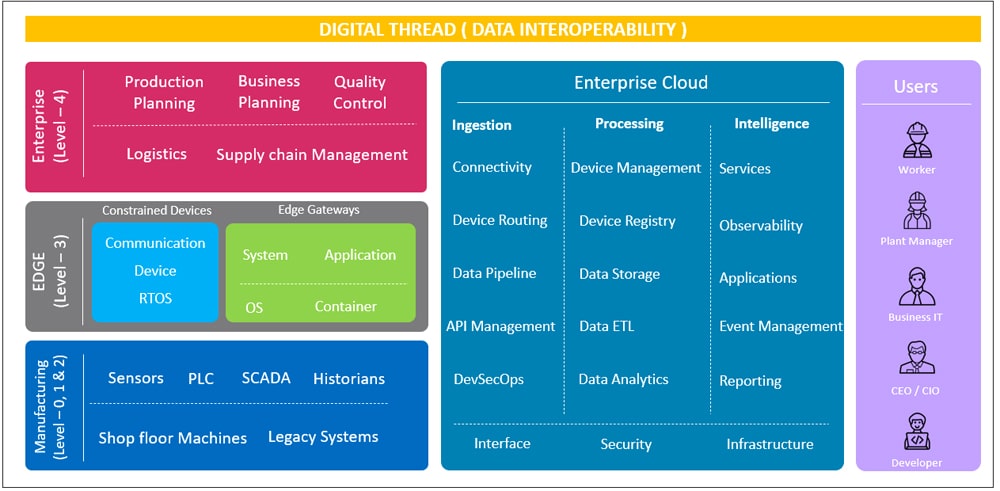

A typical manufacturing or shop floor consists of legacy systems, sensors, PLC, built-in production automation processes, SCADA, and a lot of other independent systems. Level 3 is usually the stage where data is gathered, and is referred to as the ‘edge’. This data is either processed locally or sent to the cloud to create intelligence from it. The hardware used in this level consists of constrained compute devices and gateways. Then comes Level 4, which consists of production planning, logistics, supply chain management and all enterprise applications. All these levels of manufacturing are bound together by data. Data is the single common digital thread that ties the manufacturing process vertically and horizontally, aiding in value generation.

All the data generated thus is stored in the cloud. Operations like data analysis and API management are done at the cloud level. Microservices like measuring, event management and observability also take place in the cloud.

Then comes the user who is at the centre of everything that is being done. Users (whether it is the CEO, a plant manager, or a machine operator) are responsible for the success or failure of the product that a factory is building. These users consume data at different levels.

A smart factory uses a large number of components and each of these components has hundreds of vendors. So a common language, that everyone can understand and work on, is needed. This is called the digital thread, and data-interoperability becomes critical here. It defines the way in which two systems talk to each other. If these systems are unable to communicate with each other, then the entire system fails. This is where open source and the open source community become important in the smart manufacturing space.

The role of a community (common platform)

This common language needs an architecture, and this can most optimally be defined by an open source community. This architecture helps all the components of the smart factory ecosystem to speak and understand the same language. This architecture is also critical to manufacturing better products and processes for the end user.

Let us take the example of a leading consumer appliance company that offers lifestyle devices that can be customised as per the needs of the end users. So, here, Industry 3.0, which is a tenet of mass manufacturing, is replaced by Industry 4.0. This basically means that the user is at the centre, and defines what he or she wants. All the components are also chosen according to what the user needs.

This company builds an interaction platform to connect end users to its products, and gives them the power to use this platform to define their needs. Then the company uses the same platform to suggest which product will match the requirements of the user. For example, the capacity of an air conditioner can be designed optimally based on the size of the room. The platform gives users the ability to customise these lifestyle goods as per their needs, choice and preference.

So, instead of manufacturing a conventional product which may not be relevant to end users, this company builds products that are defined by them. It builds a platform where all the components of the product can be 3D printed. This is where additive manufacturing and 3D manufacturing are combined into the entire ecosystem. This is the power of a common system, where the user is at the core of the entire ecosystem.

The power of having a common data layer built into the platform enables the company to skip the middlemen, as it is able to directly ship the products from its factory to the end user.

Another interesting case study is about an India based confectionery manufacturer. The chocolates that this confectioner is producing are temperature-sensitive. Refrigeration of these chocolates at the retail point is of utmost importance to the brand for the consumer experience, sales and market capture.

The company is not very sure how the entire ecosystem will play out if it invests in building a common platform. At present, the compressor is being sold to the cooler manufacturer, who is selling the cooler to the confectionery manufacturer. The latter then labels it and passes it on to the retailers. There is no mechanism to find out what the retailers are storing in these coolers and whether they are even placing them inside their shops.

Now, if a consumer sees brand A’s products being stored in brand B’s cooler, the whole investment in getting a cooler and branding goes to waste. The customer not only gets confused but might end up buying Brand A’s products. Moreover, sales can also get affected if the cooler is not functioning properly. A common platform can be of great help in such a scenario.

What do these use cases teach?

In order to speak to the entire ecosystem, you need to have an open mindset and an open framework that you can operate.

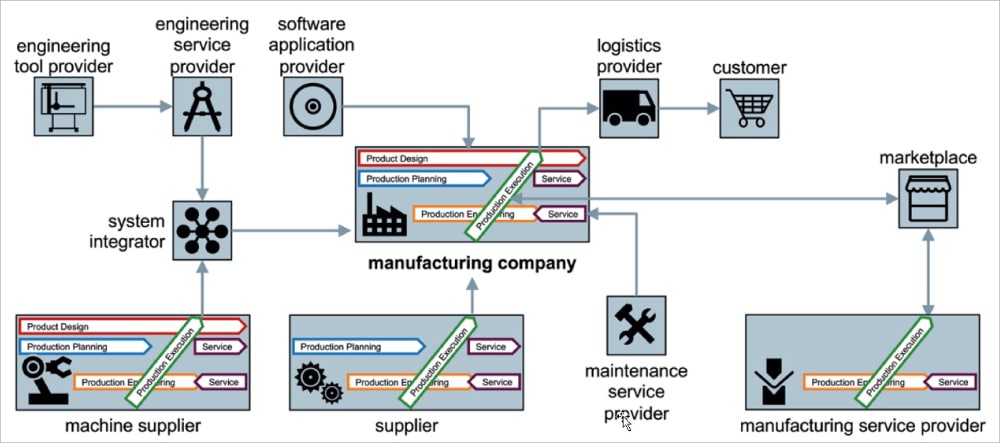

Both these use cases indicate that the reasons that make products successful go beyond how well they have been manufactured or developed by an organisation. The manufacturing may be the core part of the process, but the other components of the ecosystem play an equally important role. Each of these components has its own design services, production units, and other such equations.

Companies need to focus on system integration and the marketplace. The systems integrator needs to develop and talk in a language that all the components of the equation can understand and function in. This enables an ecosystem where every machine can talk to each other.

The marketplace is the second point where the focus should be, as it saves time in finding and sourcing essentials when needed. For example, if a company needs 3D printing material, the marketplace allows it to be found in minutes. This marketplace should be able to understand needs and amplify your message of requirement when needed.

If the marketplace is built on open source terminology, there can be a better understanding of the requirements due to the nature of the framework.

Why you need a community

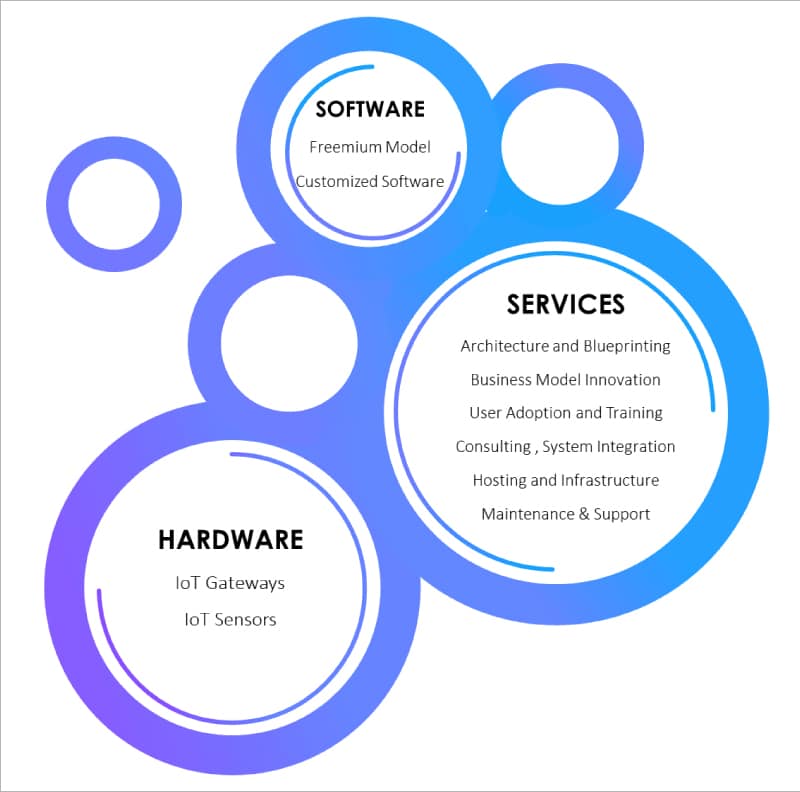

The first step towards building a community is a consortium. A consortium, defined simply, is a group made up of two or more individuals, companies, or governments that work together to achieve a common objective. The consortium is responsible for defining the format, as well as defining and publishing the reference architecture. A community adopts and owns such architectures, and makes them better.

The OPC Foundation defines how a machine will talk to another machine. The community then uses the framework given by OPC as a reference and comes out with standards like IEC62541. The community, in a nutshell, is responsible for coming out with frameworks that machines use to talk with each other.

The need and importance of a community can be better explained with the example of the English language. The framework that was defined hundreds of years ago is helping people from different countries and continents to interact with each other today. Similarly, the open source frameworks adopted by different machines and factories allow different components to generate and transmit data from one point to another.

You can go to any part of the world and converse with people if you know English as a language. Rulesets are needed, and communities play an essential role in letting different components adopt these rulesets. Then the community builds on top of these rulesets, gives feedback, and also makes sure that everybody follows that.

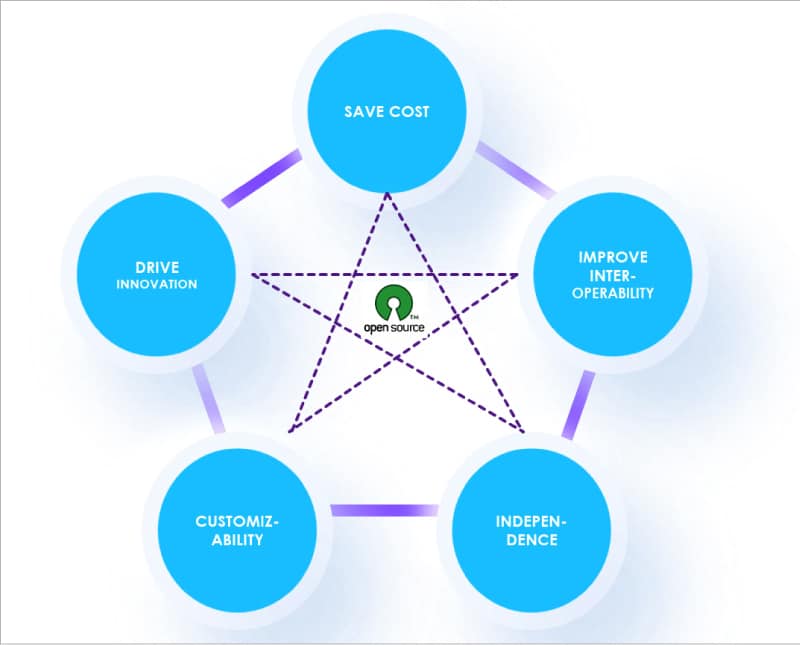

An open source community also helps in saving costs, as a company does not need to invest in developing new software. Knowing what exists in the market gives one the choice to explore and deploy the framework that best suits one’s needs. Open source communities also allow building applications on top of existing frameworks. Companies can find out the way the software is written and APIs are defined, which can help in connecting all the components and making applications and usage better.

Independence, customisability and innovation are three more advantages of having an open source community. These three go hand-in-hand and allow companies the freedom to choose between components, system players, and vendors. This is where the power of open source comes in. Everything is open, including the customisations.

Brett Cannon, the Python core developer, said: “I came for the language (Python). I stayed for the community.” This is a very powerful quote defining the value a community brings in. It goes without saying that the whole community is bigger than the sum of its parts.

The article is based on a talk given by Bharath Sridhar, engineering manager, Industry 4.0, at Open Source India 2021.